Homogeneous System

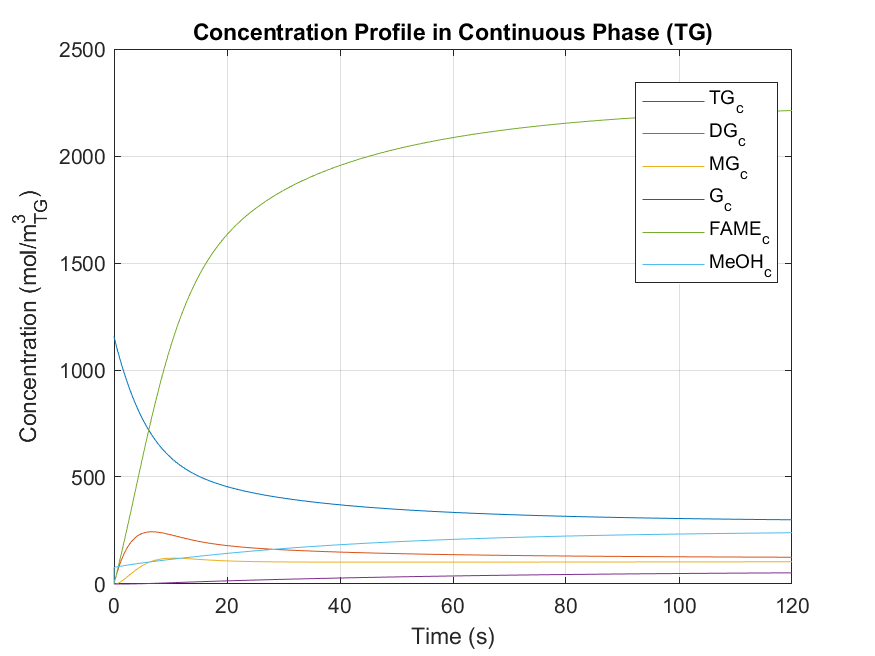

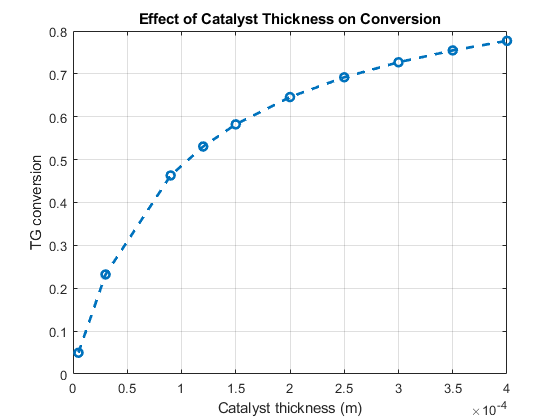

The homogeneous system models a two-phase transesterification reaction catalyzed by NaOH in methanol, dispersed within triglyceride-rich oil. The simulation captures phase-specific reaction kinetics and mass transfer limitations. At 100 rad/s, the conversion reached 74%, with excess methanol shifting the system from diffusion-limited to kinetically driven performance.